Boat Master

I designed and developed 'Boat Master' to provide an easy way to practice berthing and navigating boats in varying conditions. It is available now on the App Store and Google Play and has almost 15,000 active users.

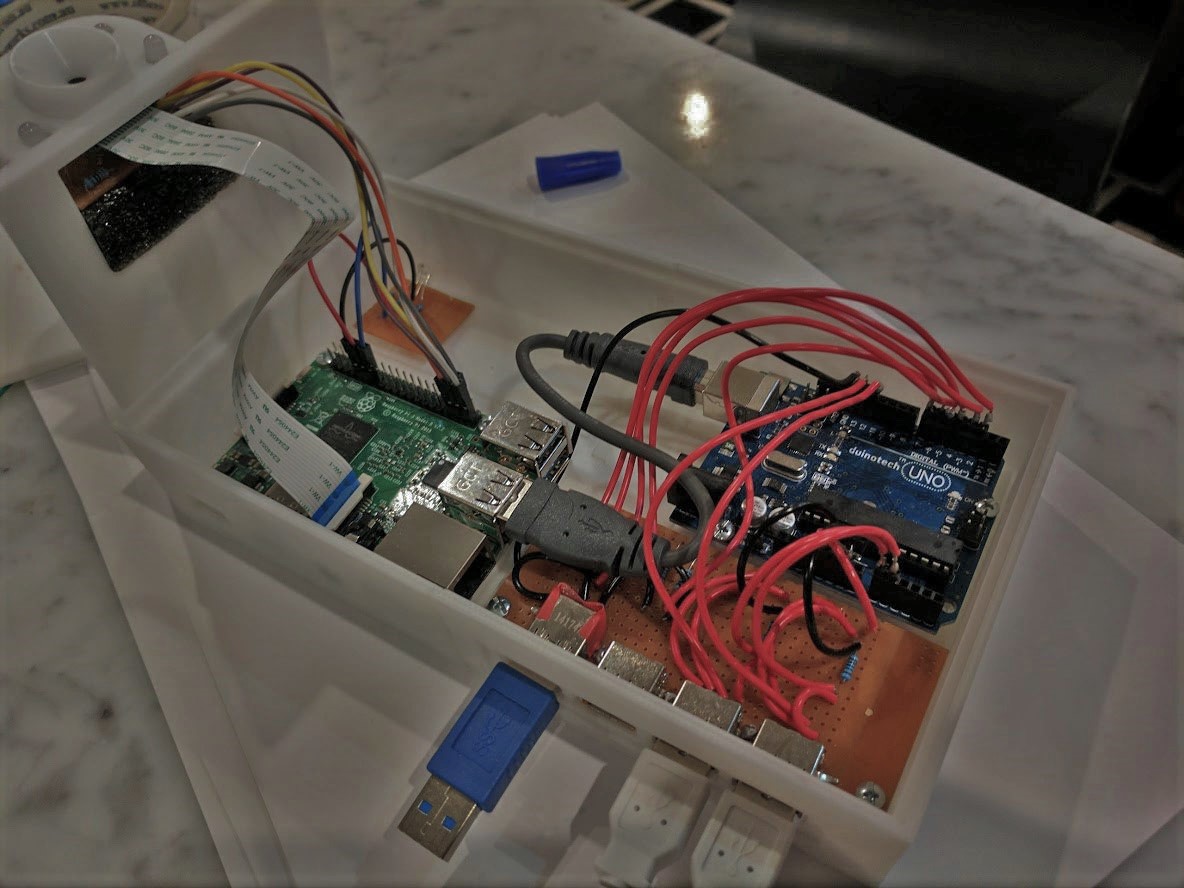

The E.R.I.C Smart Fridge System

The 'Electronic Refrigerator Information Centre' was my year 12 Design and Technology Major Project. It is a system I designed which could be installed in any fridge and then could use sensors to measure the amount of milk or eggs in the fridge, then send that information to an web app that the user could use away from home.

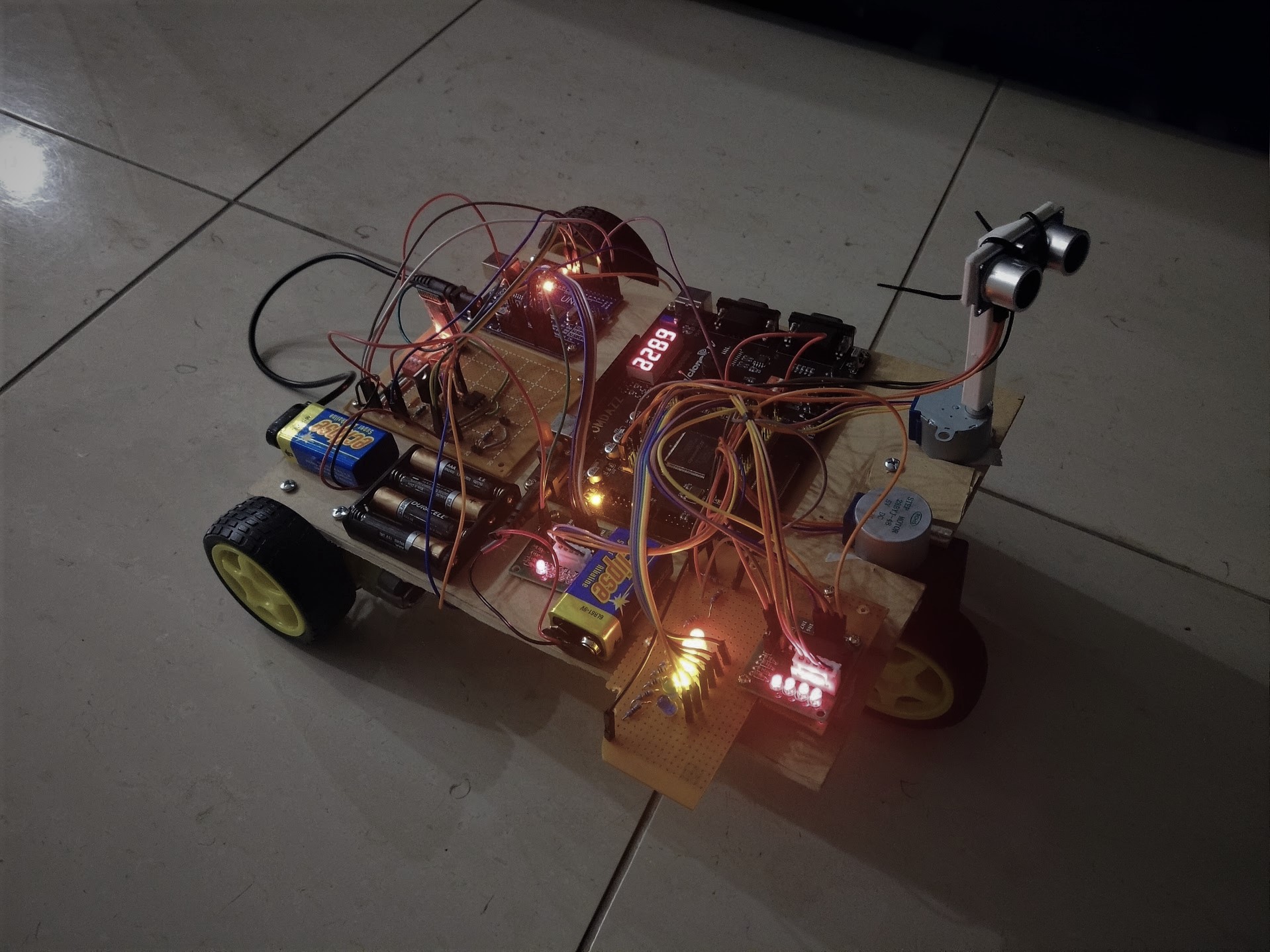

Bluetooth Controlled Car with Crash Prevention

As part of Mechatronics 1, I elected to take part in the 'unleashed' programme for both the FPGA and the MCU (Atmega328p) Assignments. This gave me the opportunity to choose what I wanted to develop. For the FPGA I developed an ultrasonic radar system, and for the MCU I developed a bluetooth-controlled car, which integrated the radar system for crash prevention.

Web Development Experience

I developed the Flat Wombat Studios website, The E.R.I.C Smart Fridge Web App and this website as well as a customer survey system utilised by Whitehaven motoryachts and the 2016 & 2017 Sydney Boat Show using industry standard web languages such as HTML, CSS, Javascipt, PHP and MySQL, as well as utilising modern tools like Bootstrap and jQueryMobile.